Researchers from the University of Jaén and the ‘Advanced Materials’ group of the Institute of Materials Science of Seville (ICMS-CSIC), in collaboration with the University of Patras (Greece) and experts from the Institute of Innovation, Science and Business, S.L., have found a use for one of the waste products generated during the production of biodiesel. This is glycerin, a fatty organic by-product that the production companies accumulate without finding a use for the large total amount generated.

In the article ‘Ceramics from clays and by-product form biodiesel production: processing, properties and microstructural characterization’, published in the journal Applied Clay Science, the Andalusian researchers, including Pedro J. Sánchez Soto, scientific researcher at ICMS and head of the ‘Advanced Materials’ group, have shown that the addition of glycerin to the clay used to make bricks provides insulating properties, especially thermal ones, due to the porosity it is capable of providing.

Glycerin, from 100 ºC of cooking temperature, releases CO2 that is trapped inside the clay, causing gaps or pores inside it. In insulating bricks, thermal conductivity is obtained precisely through pores evenly distributed in their internal structure. The greater the number of small pores and the less interconnection between them, the lower the thermal conductivity and, therefore, the greater the insulation and energy savings.

According to the researchers, although the use of renewable energy and, specifically, the use of biodiesel, can reduce greenhouse gases by between 57% and 88% for each kilometer traveled compared to fossil diesel, there are still residues from the process that can be recycled. “These new fuels generate a series of wastes that cannot be reintegrated into the same manufacturing process. For these cases, brick ceramics not only serve as a deposit for the inert residue, but can have a positive effect on the material, as is the case with glycerin, which also allows the porosity to be controlled and made to measure,” says one of the authors of the study, Luis Pérez-Villarejo, professor at the University of Jaén and collaborator of the ICMS, who has actively participated during the characterization phase of the materials.

Improving the properties

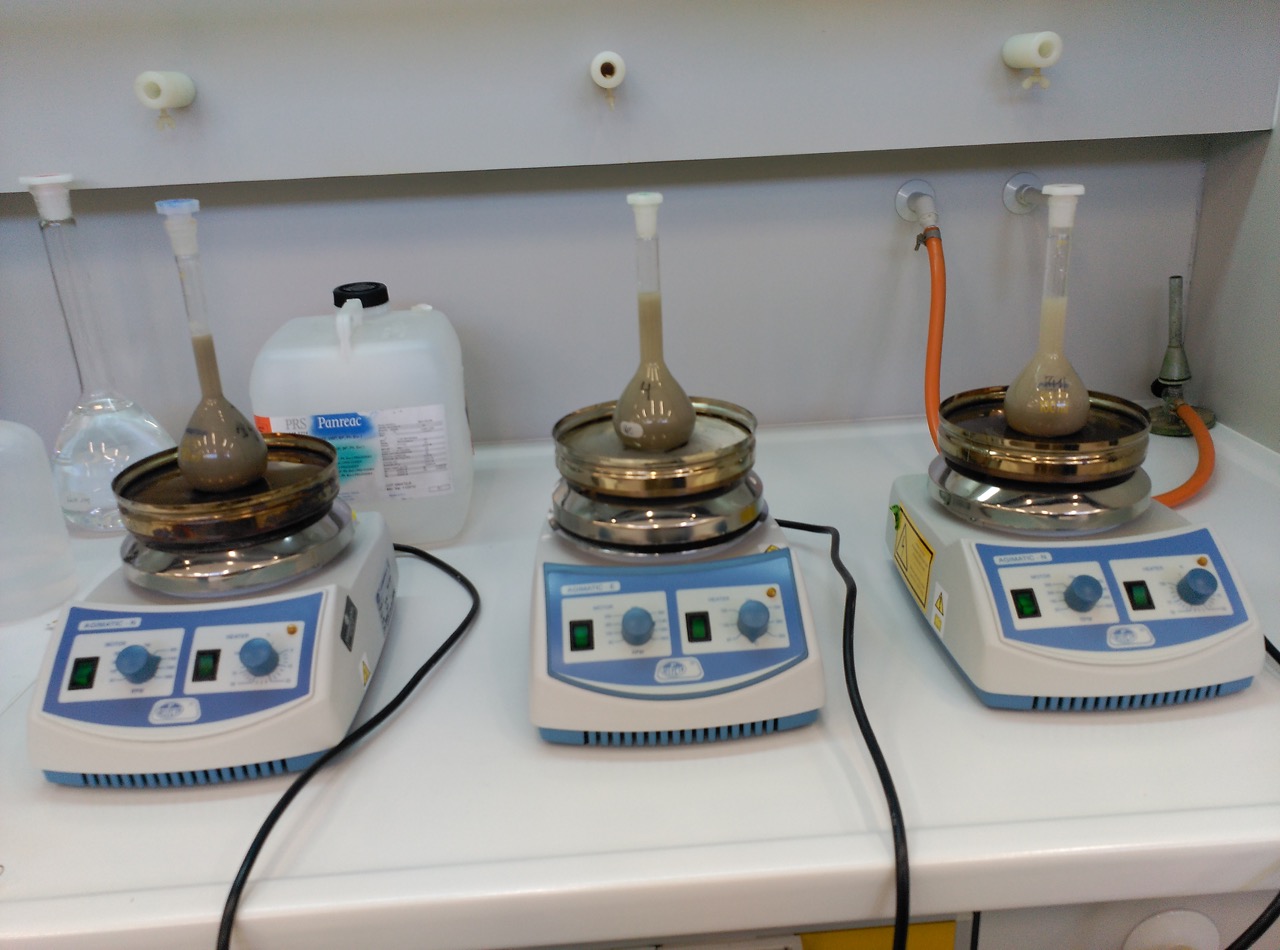

The researchers prepared ceramic compounds based on clays to which they added glycerin in different proportions and then subjected the mixture to conventional molding and processing methods, as well as firing and cooling. The clays were extracted from a quarry located in Bailén, while the glycerin was provided by the Linares biodiesel company LIBITEC (Linares Biodiesel Technology) that works with soybean, sunflower and palm oils.

The results showed that the addition of this residue improved the technological properties of the ceramic products. Specifically, during the research phase, percentages of glycerin ranging from 5% to 20% were added to the clay. The thermal conductivity, the type of porosity generated, the resistance to compression, the absorption and suction of water or the density, among other properties, were evaluated in the compounds obtained.

The authors of the study concluded that by adding between 10% and 15% of glycerin to the clay, sufficient plasticity was generated to significantly increase its insulation capacity, especially for thermal purposes, while maintaining the resistance values required of materials used in construction. “With just the addition of 15% glycerin, the thermal conductivity of the brick drops by half,” says Pérez-Villarejo, who also points out an improvement in acoustic insulation. The researcher highlights the environmental benefits that this study brings, since it provides an outlet for a large amount of waste generated by the growing biodiesel industry, while providing new materials that make sustainable construction more viable and facilitate energy savings.

Source: Fundación Descubre