Source: CSIC Communication

A study involving Gerardo Colón, from the Institute of Materials Science in Seville, together with researchers from the Institute of Catalysis and Petrochemistry, also from the CSIC, and the European Synchrotron Radiation Laboratory in Grenoble (France), reveals the phases that produce hydrogen in a photocatalytic copper and nickel system, and opens a new path for the production of what is known as “green energy”.

Hydrogen is considered one of the most promising fuel options due to its energy storage capacity, about three times greater than natural gas, and the absence of pollutant generation in its combustion, since it only generates water in the process.

Photocatalysis allows hydrogen to be produced through a “complete green process”, one of the main objectives of modern chemistry, since it occurs under mild temperature and pressure conditions and also allows sunlight to be used as an energy source for radiation.

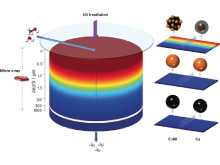

Photocatalysis requires the use of a semiconductor. Under light excitation, the material generates charged species that, upon reaching the surface of the material, interact with the molecules and produce the chemical reaction. In this study, the researchers have worked with copper and nickel systems as active elements deposited on the semiconductor and have proven that the combination of both is more active than the copper or nickel system separately.

“To generate hydrogen, it is necessary to include metallic elements on the surface of the semiconductor. One of the problems is knowing the active metallic phase in the chemical process, which is complex in photocatalysis since the volume of sample analyzed must be exactly the same as the illuminated one,” says researcher Marcos Fernández-García, from the Institute of Catalysis and Petrochemistry.

Understanding how the active phase of a photocatalyst modulates its oxidation state, size and structure during the photocatalytic reaction is one of the most complex tasks. “For the study, the interaction between matter and radiation is calculated, in addition to controlling the volume of the sample scanned by X-ray absorption and thus ensuring that the results of the metallic phases are relevant,” says Fernández-García. “The properties of the active phase in the catalysts are analysed —he continues— as a function of the distance from the surface. With this, the effect of the reactants and the light are analysed separately.”

Depending on the depth from the surface of the sample, the state of the metal is different. “Under the simultaneous action of light and reactants, the metallic elements undergo a transformation, where both metallic and oxidised phases are observed. In the bimetallic system, which has a more extended oxidised phase, very small particles of the metallic phase are generated, which are dispersed throughout the solid. This difference causes the production of hydrogen to increase between three and 10 times, depending on the experimental conditions,” concludes Fernández-García.

This study has been published in the journal Angewandte Chemie. More information in: M. J. Muñoz-Batista, D. Motta Meira, G. Colón, A. Kubacka, M. Fernández-García, Angew. Chem. Ed. 2018, 57, 1199.